recarb® – The EJOT way to achieve your sustainability goals

recarb® programme

In order to achieve the transformation to a sustainable supply chain, we at EJOT focus on building supplier relationships that support us and our customers on this journey. For a large part of the EJOT product portfolio, tempered steel in wire form is the starting material for the manufacture of our products. Depending on the complexity of the end product, this is done in a multi-stage cold forming process.

The recarb® programme uses CO₂-reduced tempered steel for the manufacture of EJOT products. This consists of a higher proportion of secondary steel (high ‘scrap content’) and is also produced in an electric arc furnace using 100% renewable electricity.

Compared to our ‘classic’ products, the wire used in recarb® products therefore enables CO₂ savings of at least 55%.

recarb® quality

Since 2023, various test batches of the CO₂-reduced wire material have undergone all production processes at EJOT. The steel complies 100% with our delivery specifications. Furthermore, we attach great importance to credibility and transparency, which we underline with the verification documents.

CO₂ emissions per product are calculated in accordance with DIN EN ISO 14067 and ISO 22095. This ‘product carbon footprint balance’ has been calculated at item level for more than two years.

A calculation tool programmed in-house for this purpose has been successfully validated by TÜV Süd in accordance with the aforementioned standards since 2025.

Purchase of recarb® products

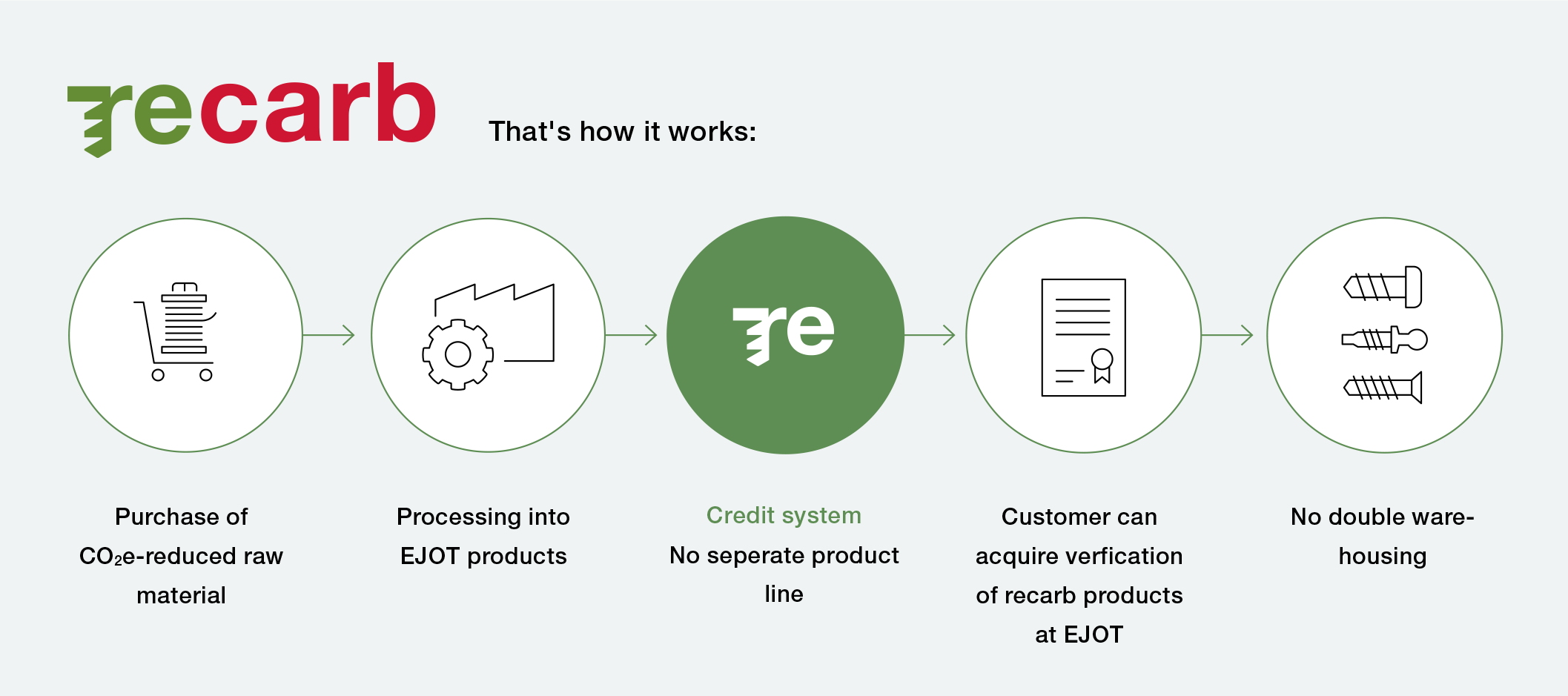

Credit method

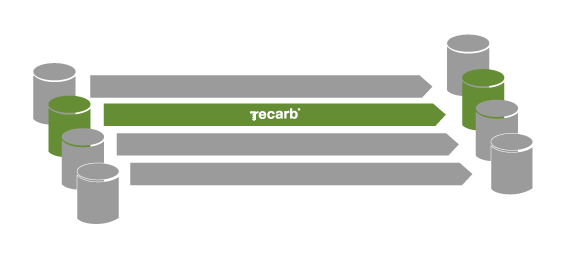

With a so-called credit, you have the opportunity to purchase CO₂-reduced products from EJOT. You decide on a specific tonnage that will be used for the manufacture of CO₂-reduced products and receive proof of this in the form of a credit. In return, we undertake to process this ‘sustainable’ tonnage in production – regardless of the physical product you actually purchase from us.

Credits can be issued for all products manufactured with tempered steel in Germany. Only the quantity that EJOT actually manufactures into fasteners is claimed per year via our credit system.

Your advantages of the EJOT credit system:

- Implementation possible for ongoing or already planned projects

- Only minor additional costs, which are not passed on to the unit price of the product

- Avoiding double warehousing leads to savings in additional costs

- Reduction of CO₂e emissions by at least 50% for your CO₂e balance of the purchased product

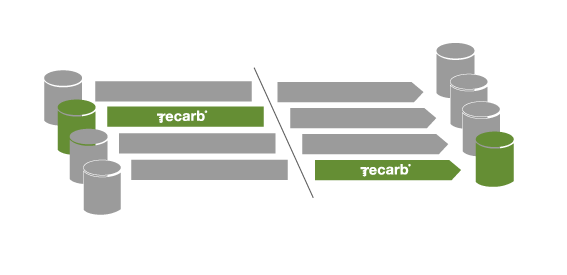

1 to 1 sale

As an alternative to the credit system, we also offer a so-called ‘1-to-1 sale’. This means that the physical boundaries of the purchased material and the product sold to the customer are maintained. In other words, you receive your desired product in a recarb® version with the corresponding CO₂ reduction. This system is only suitable for new project awards, as separate product lines are created in this case.

We are here to help

Join us on the path to a sustainable supply chain. To receive a recarb® quote for your project, please contact your EJOT application engineer or our technical hotline (tel.: +49 2751 529-123, email: hotline@ejot.com).

Reduce your CO₂e emissions now. We will be happy to assist you with your recarb® order process.